TIGEMASTER TM4

Machine à couper les tiges

et visser les couronnes

Enginered and made in Switzerland

The TigeMaster 4 (or TM4) is a machine for assembling watch winding rods.

It cuts the rods and then screws and glues the crowns.

Machine functions

- Robust and reliable.

- Loading of crowns in hidden time.

- Calculation of total number of pieces and number of pieces per hour.

- Pneumatic opening of winding stem and crown clamps.

- Cutting speed adjustable from 10 to 200 %.

- Automatic wheel wear compensation.

- 2 work cycles: stepped or automatic.

- Highly flexible (with or without screwing, gluing, cutting, etc.).

- Dust suction system (very quiet).

- RS-232 output.

- Option :

- Colmaster CM1 gluing device

- Lasermaster LM1 control laser

- CVLT

Technical specifications

Supply voltage :

Power :

Min. input pressure :

Resolution :

Languages :

Weight :

Dimensions (l/d/h) :

110-230 V / 50-60 Hz

350 W

5 bar

± 0.01 mm

FR / GB / DE / IT

34 Kg

491 x 521 x 335 mm

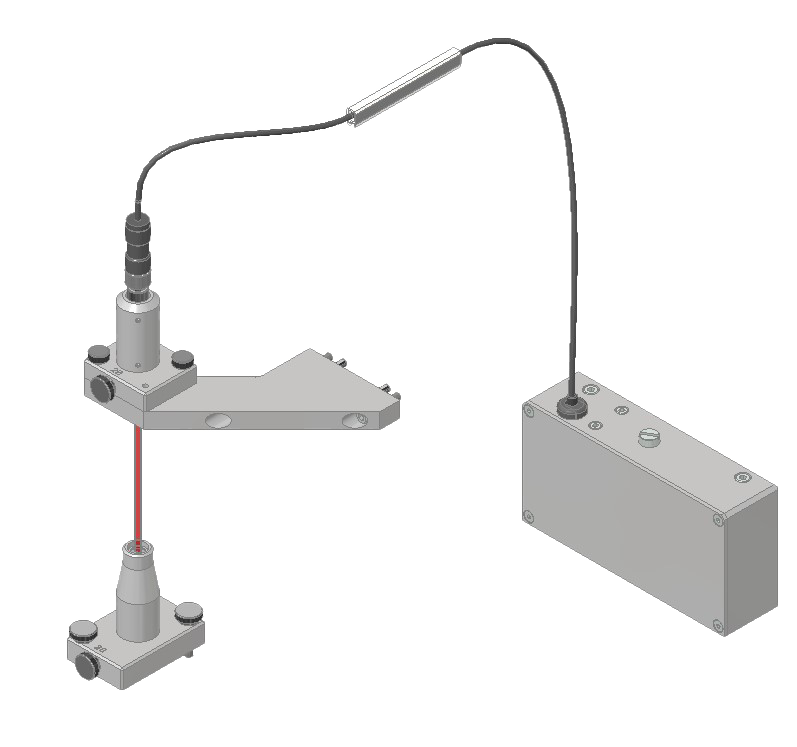

*Accessories: Colmaster CM1 / Lasermaster LM1.

*Winding stem and crown clamps sold separately.

Available options

Colmaster CM1 (Gluing device)

- Controlled by TIGEMASTER TM4

- Automatic glue level correction

- Glue laying pressure and time adjustable

- Long-lasting anti-drying system

Weight : 3Kg

Dimensions (l/d/h) : 240 x 150 x 250 mm

LASERMASTER LM1 (Dispositif de détection laser)

- Crown front face detection

- Avoids the need for systematic checks

Weight : 0.253Kg

Dimensions (l/d/h) : 116 x 106 x 281 mm

CVLT

- Digital comparator to display the length of the rod and facilitate adjustment