UNIROX

Airtightness checking machine by volumetric comparison

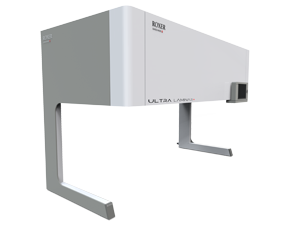

SMARTROX

Airtightness tester for Smartphone

About us

Presentation

ROXER SA is based in La Chaux-de-Fonds, the cradle of the Swiss watchmaking industry, and has a workforce of 30. A specialist in water resistance testing, the company exports approximately 15% of its products to Europe, Asia and the Americas

In the fields of both mass production and After-Sales service, ROXER SA offers a wide range of watch water resistance testing devices, using either air or water. An undisputed leader in hand fitting, both manual and semi-automatic, ROXER SA also offers stem cutting machines, as well as presses for screwing and driving down watch case-backs or crystals.

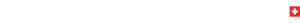

We help control dust, the kinds that can impair the operation of your products. A leader in the field of brushes and blowers used in casing. ROXER SA also offers individual laminar flow systems tailored to each workbench, in order to obtain an uncontaminated atmosphere, as well as ionisation systems to prevent dust deposition on surfaces.

We are leaders in the field of brushes and blowers used in casing. ROXER SA also offers individual laminar flow systems tailored to each workbench, in order to obtain an uncontaminated atmosphere, as well as ionisation systems to prevent dust deposition on surfaces.

The current structure of the company enables it to offer our customers, as well as a host of standard products, solutions customised to the most stringent requirements. All ROXER products are guaranteed for one year, and the quick After-Sales service means that you can be sure of a high degree of productivity.